Product Series

Ten years focusing on bicycle accessories quality service guaranteed

Hot Products

News

About Us

Shenzhen Hanhonghxin Precision Technology Co., Ltd. is a professional company integrating the design, R&D, production and sales of motorcycle and automobile parts, outdoor sports equipment parts, lithium batteries, bicycle parts, medical machinery parts, electric scooter parts and hardware and electronic copper and aluminum stamping and forging parts. Established in November 2013, the company now has advanced production equipment and professional technical personnel. Adhering to the tenet of "customer first, quality first", we provide high-quality products and services to new and old customers in the industry. Our products are mainly sold to Europe, America, Southeast Asia and other countries, and are deeply trusted and praised by our partners. We are committed to building a global brand "LUNJE" and establishing an image label in the industry. The company will continue to adhere to the development concept of "integrity, innovation, professionalism, and win-win", continuously improving the comprehensive competitiveness of the domestic and international markets. The company is also more willing to work hand in hand with our customers for common development and create brilliance!

Factory Area

Daily Output

Production Equipment

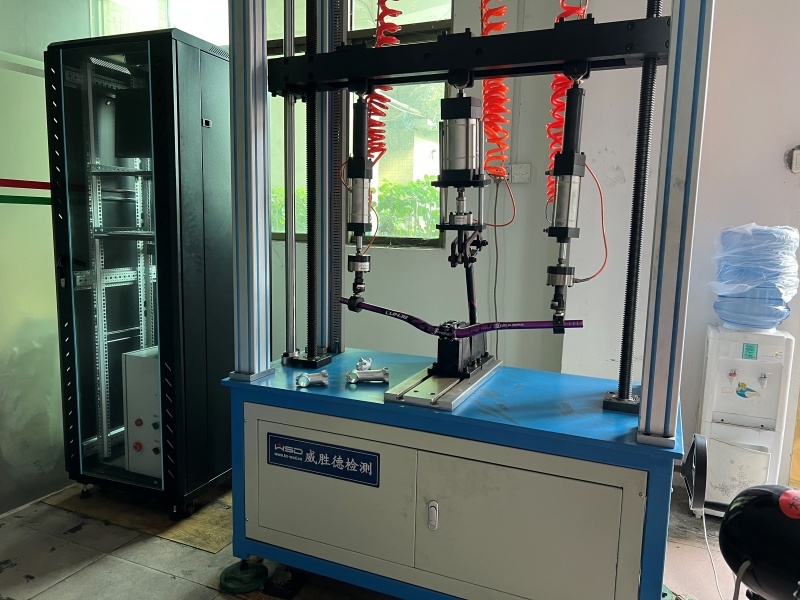

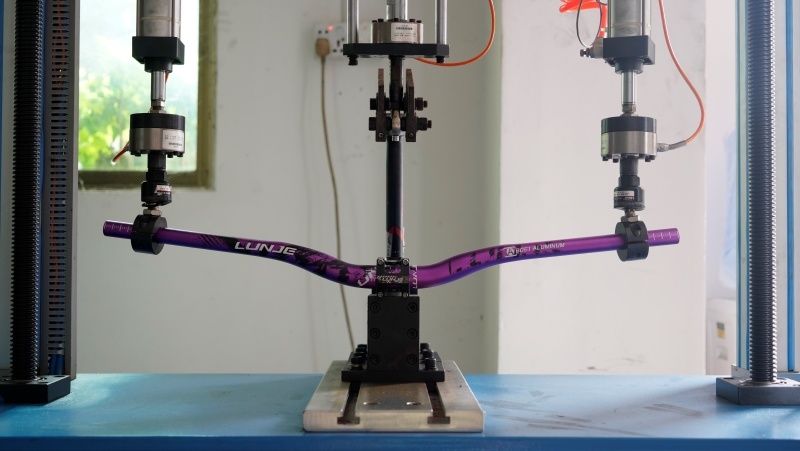

Han Hongxin Technology Super Factory

Specialized Production Equipment:

The company is equipped with internationally advanced stamping, forging, and precision machining equipment, including multi-station presses, CNC machining centers, and precision measuring instruments, ensuring that every stage of product production, from raw materials to finished products, meets the requirements of high precision and high consistency.

Mature Technical Team:

We have an experienced R&D and production team with full-process technical capabilities, from mold design and process optimization to mass production. We can efficiently meet the customized needs of complex components such as motorcycle parts, lithium battery components, and medical machinery parts.

Strict Quality Control:

Adhering to the principle of "quality first," we implement the ISO quality management system. Through multiple controls such as raw material selection, process full inspection, and finished product performance testing, we ensure that products meet international standards (such as CE, RoHS, etc.) and meet the strict requirements of European, American, and Southeast Asian markets.

Diversified Product Capabilities:

Our products cover multiple fields, including motorcycle parts, outdoor sports equipment, and electric scooter parts. We specialize in the precision stamping and forging of copper and aluminum metals and support small-batch trial production to large-scale delivery, flexibly responding to customer needs.

Support ODM/OEM processing customization

Professional production equipment, technical team, service team, provide you with comprehensive services. We are not only a factory, but also a strong supplier behind you

Inquire Now

Inquire Now